WELCOME TO PODRIDE

NEWS

LATEST PODRIDE NEWS

By Romplestamper

•

19 Dec, 2019

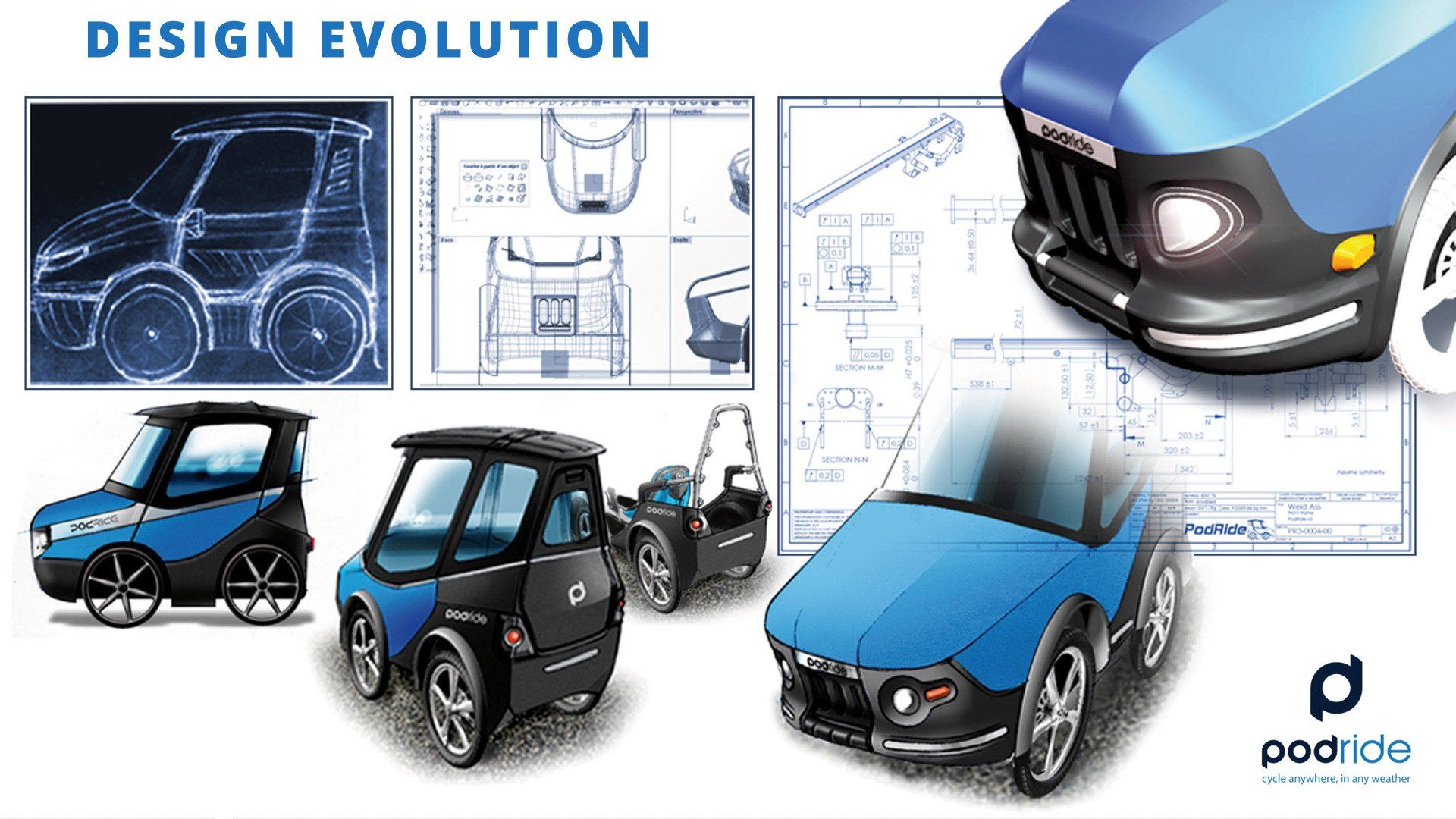

Dear PodRide Supporter, Time for another update on PodRide’s development, just in time for Christmas. NEW PROTOTYPES We’ve been quiet, but working towards the production of new prototypes. We experienced some unexpected and significant technical problems in changing the format of our 3D models from that produced by our designer to that used by our […]

By Romplestamper

•

15 Jul, 2019

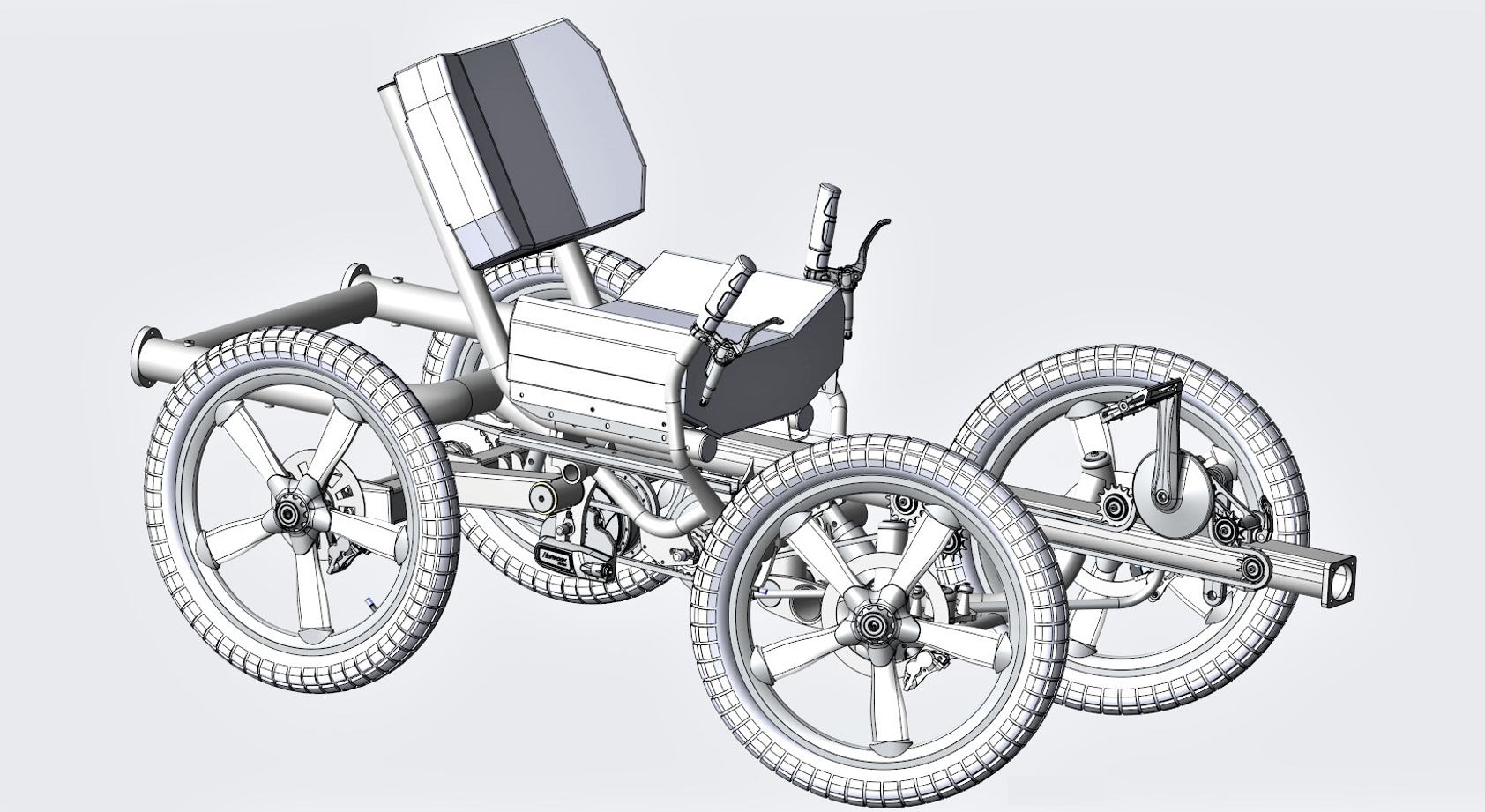

Dear PodRide Supporter, Time for another update on PodRide’s development. We’re happy to report that we’re making good progress. In April we mentioned that we had brought on a new team member in Mike Singleton whose mandate was to reduce the number of components, complexity, cost and weight of PodRide. We also mentioned that he […]

04 Apr, 2019

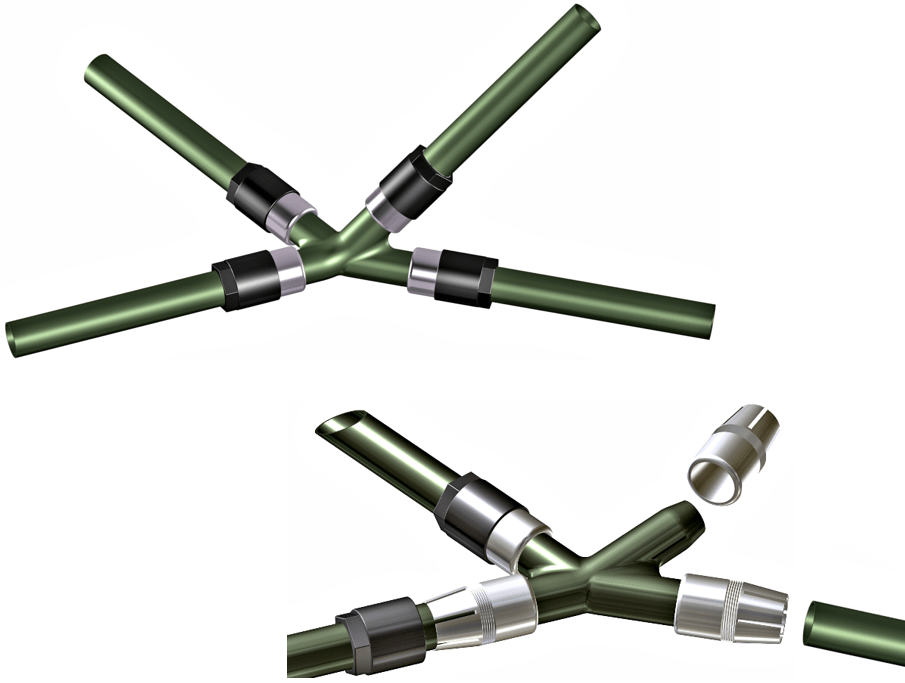

Dear PodRide Supporter, Time for another update on PodRide’s development. In our last update we mentioned that we were not satisfied with the high number of custom parts and the associated complexity in the PodRide design. The design had too many custom components, which translates to higher production costs, more manufacturing and assembly issues, a […]